In the intricate world of cable maintenance where accuracy and durability is paramount, the use of modern tools like wire rope lubricators as well as wire cleaners has become indispensable. These innovative devices are crucial in ensuring that cables operate efficiently and last longer in a wide range of industries. Wire cleaners and rope lubricators are vital for the maintenance of cables. In this post, we examine their roles, benefits and their transformative effects on the overall effectiveness.

Understanding wire rope lubricators

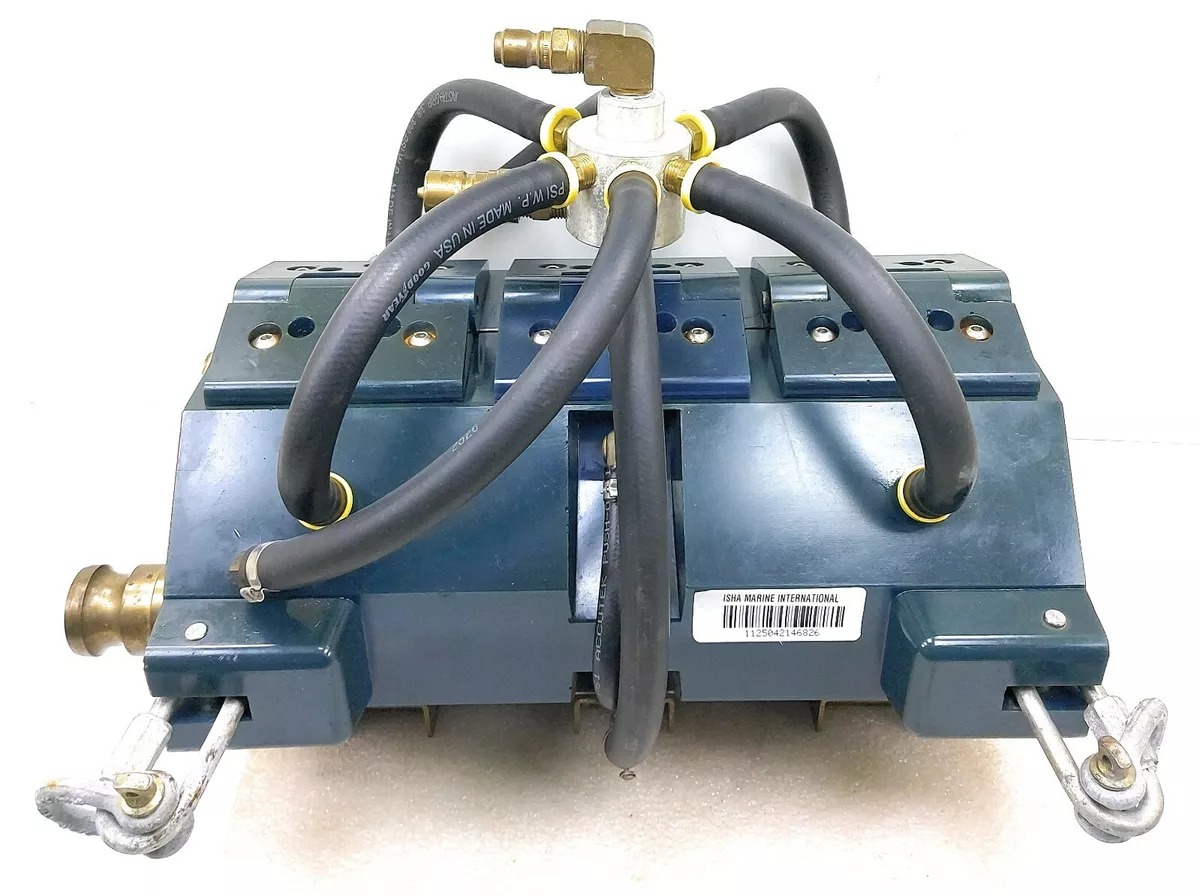

Wire Rope Lubricators are machines that allow you to grease wire ropes in an organized method. This process is vital to stop rust from occurring, as well as reducing friction and increasing the overall endurance. The lubricator is responsible for ensuring that the lubricating ingredients are evenly distributed over the length of wire ropes protecting them from wear and tear.

How to keep cables clean with wire cleaners

Cleaners for wires (also called cable cleaners) are also important in maintaining the cleanliness and hygiene of cables. They are intended to get rid of contaminants, debris and fluids that may accumulate on the cable during different actions. The use of wire cleaning products is particularly important in areas where cables are exposed to harsh conditions, thus ensuring maximum performance while avoiding damage.

Optimizing Cable Lifespan:

The combination of wire rope lubricators as well as wire cleaners are significant in extending the lifespan of cables. By applying lubrication in a systematic manner using wire rope lubricators, and then removing pollutants with wire cleaners cables are protected from the detrimental impacts of friction, corrosion and external factors. The cable’s integrity is preserved, resulting in increased performance and less maintenance expenses.

Effectiveness when applied

Wire rope lubricators are made for easy use and efficiency in application. These lubricators are versatile and are suitable for a wide range of wire rope types and sizes. The methodical and automated application of lubrication guarantees consistency and eliminates the possibility of inconsistency that manual processes can cause.

In a challenging environment, adaptability:

Lubricators for wire ropes, and wire cleaners are essential in the sectors where cables are required to endure extreme conditions, such as the ones found in drilling, construction or maritime operations. These devices are designed to endure harsh conditions and are reliable cable maintenance tools in a variety of conditions.

Solutions for maintenance that are cost-effective:

In the long-term using wire cleaners and wire lubricators in order to maintain cables is an effective strategy. The initial investment for these tools is minimal compared to the cost-related issues like repairs and replacements of cables caused by improper maintenance. Know more at Wire Cleaning

Conclusion:

Lubricators and cleaners for wire wire ropes are the guardians who ensure cable integrity and accuracy across a variety of industries. The consistent application of lubrication and removal of contaminants contribute to the longevity of cables, eventually cutting down on maintenance costs and improving the efficiency of operations. Cables are still used in the most critical sectors, therefore the use of tools to maintain cables that help keep them in good working order and successful is crucial.