Innovation is essential to the success of the medical devices business. Bringing groundbreaking concepts to life requires a reliable partner who can translate ideas into tangible prototypes and, ultimately, top-quality production components. Influx Labs fills this crucial job by providing a complete solution for medical device companies seeking the best in CNC machine machining and prototype manufacturing.

From Dream to Prototype: Influx Labs Facilitates Medical Device Innovation

Medical device companies often face a complex journey, from initial conception to launch. Influx Labs recognizes the value of prototyping in this process. They provide a friendly and supportive atmosphere to turn your innovative ideas into prototypes that can be tested, allowing for you to test and refine your ideas as well as collect feedback prior to making a decision on large-scale production.

Influx Labs Expertise on CNC Machining

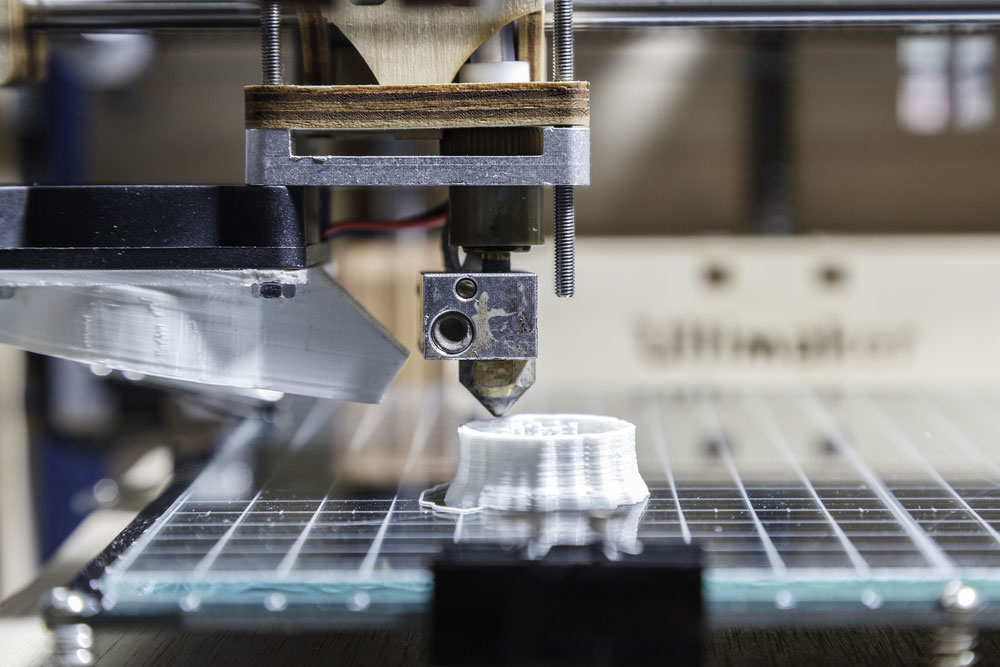

Influx Labs’ core competency is their innovative CNC machining technology. Computer Numerical Control machining (CNC) employs computer-aided programming to precisely control cutting tool, making it possible to create highly precise and intricate parts. Influx Labs is able to make medical device prototypes as and production parts that conform to the most stringent medical device requirements.

Beyond Prototyping: Scaling Up for Production

Influx Labs’ services extend beyond the realm of rapid prototyping. Their experience with CNC machine tools permits them to seamlessly move from prototype development to high-volume production runs. It eliminates the need to have an additional manufacturer while ensuring that the product is consistent in its final form and prototype.

Affirmed Commitment to Quality Materials Trackability and Certifications

Influx Labs is aware of the significance of quality in the medical device industry. Influx Labs utilizes a system which ensures complete material tracking throughout the entire manufacturing process. This will ensure that you’re fully informed about the materials you use for the production of your prototypes. Furthermore, Influx Labs can provide materials and finishing certificates upon your request, giving you peace of mind while meeting stringent regulatory requirements.

The Influx Labs Advantage: Why Choose Them for Your Medical Equipment?

A variety of factors distinguish Influx Labs apart from other prototyping and machining firms. Influx Labs is a great partner for medical device development

Affirmedly committed to Medical Devices: Influx Labs knows the special requirements of the medical device industry. They have the experience and expertise needed to produce high-quality components for medical devices.

Precision Engineering: Their advanced CNC machining capabilities ensure consistent results and unbeatable accuracy essential for the creation of functional and robust medical devices.

Influx Labs is a one-stop-shop for prototyping as well as production. This saves you the hassle of locating several suppliers.

The Quality Commitment: Influx Labs is committed to high-quality products, from material traceability to certifications. We make sure that your medical devices conform to strict guidelines.

Influx Labs – Accelerating your Medical Device Development Journey

Influx Labs’ expertise in prototyping and CNC machining lets medical device companies to bring fresh ideas to life quicker and with more efficiency. Through a partnership with Influx Labs, you gain access to:

Lower Risk: Prototyping allows you to discover and fix potential problems earlier in the development phase which reduces risks associated with production at full scale.

Influx Labs streamlines prototyping, production and delivery of medical devices. This lets you get your product to market quicker.

Improved Design Refinement: Physical prototypes allow extensive testing and feedback from users and allow you to improve your design with greater confidence.

Influx Labs can help you discover the full potential of speedy prototypes and high-precision CNC machines. Be amazed as your medical device ideas become reality and define the future of healthcare.